According to Duden, “glass” is briefly and concisely defined as follows:

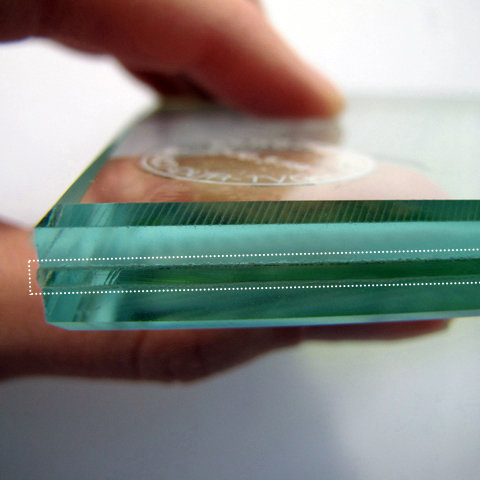

A translucent, usually transparent, easily fragile substance made from a molten mixture and used as a material (e.g. for panes, glasses).

We are all familiar with this substance and yet we know very little about it. Perhaps this often transparent material does not catch our eye enough. It is also possible that we have simply become accustomed to this versatile material. Glass is used as a tasteless container for breakfast juice and on the way to work this material protects us from environmental influences - regardless of whether we travel by car or train. Glass is also immune to most acids and alkalis, which guarantees a wide range of applications.

While showering at least, most of us come into contact with glass again. In this case not simply with glass, but with two differently refined special forms of it, which we will briefly discuss in the following.